ATOP Glass Mosaic Tiles PVD Coating Vacuum Metallizing Machine

Product Application

1. Metal. Resin. Glass, ceramic materials such as cup. Hood. Arts and crafts. Decorations. Toys and other

products surface plating aluminium. Nickel. Chromium metal film. Turn on the surface of the plating has

metal feeling or red. Purple. Blue. Green light, etc.

2. Faucet. Spray. Shell. Case. Frame. Knife. Hardware. Ceramic pieces, etc., for decorative film or

functional film.

3. Gear. Hemp drill bit. Tap, die, etc.

4. Applicable to metal, ceramics, glass and other materials, such as hard metal film, metal compound film

and decorative film.

5. Widely used in the surface treatment of watches, glasses, information products, tools, molds, hardware,

glass, ceramics, building materials and other industries.It is the ideal equipment for plating IP imitation

gold, IPCr, IP light gun, IP coffee, IP rose, champagne gold and cognac.This machine does not pollute the

environment, the coating layer is not toxic, it is harmless to the human body, it is the solution to the water

electroplating factory's environmental pollution problem, the replacement of traditional hydropower plating

gold, chromium plating the ideal equipment.

|

Product Name

|

ATOP Glass Mosaic Tiles PVD Coating Vacuum Metallizing Machine

|

|

Vacuum Chamber Size

|

Decide according to the substrate size and output

|

|

Substrate

|

Hardware,glass crafts,ceramic crafts,such us watches,mobile phone metal

shell,sanitary ware,mould,electronic products,crystal glass, glasses, cutlery, knives

and so on

|

|

Coating Film

|

High-grade decorative coating.

|

|

Coating Color

|

Gold, rose gold,coffee,brown,bronze,blue,black,white,gray etc.

|

|

Applications

|

Hardware,glass crafts,ceramic crafts such us watches,mobile phone metal

shell,sanitary ware,mould,electronic products,crystal glass, glasses, cutlery, knives

and so on.

|

|

Structure

|

Vertical type ; horizontal type ; single door type ; double-door type.

|

|

Coating Material

|

Stainless steel, aluminum, titanium, tungsten and other metal films may

be manufactured as coated TIN, TIC, TICN, TIALN, CRN, CU, AU, diamond film

(DLC), decorative film metal, film and non-metallic composite coating film and its

compounds film.

|

|

Features

|

High pumping speed, high efficiency, energy saving, full automatic process

controller can be simple, reliable, beautiful.

|

Working Principle

Vacuum arc ion coating machine working principle is to put the vacuum arc discharge technique used in

the evaporation source technology, namely the ignition under vacuum evaporation source (cathode), and

self sustaining formed between anode arc discharge, the cathode arc light point out cathode material of

the ions.The joule heat generated in the current local concentration, make the burst of cathode materials

local ionization, such as in the workpiece under the action of bias in combined with the reaction gas, which

form the plating film is deposited on the workpiece surface layer.

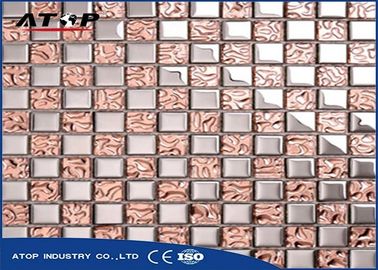

Coating Samples

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!